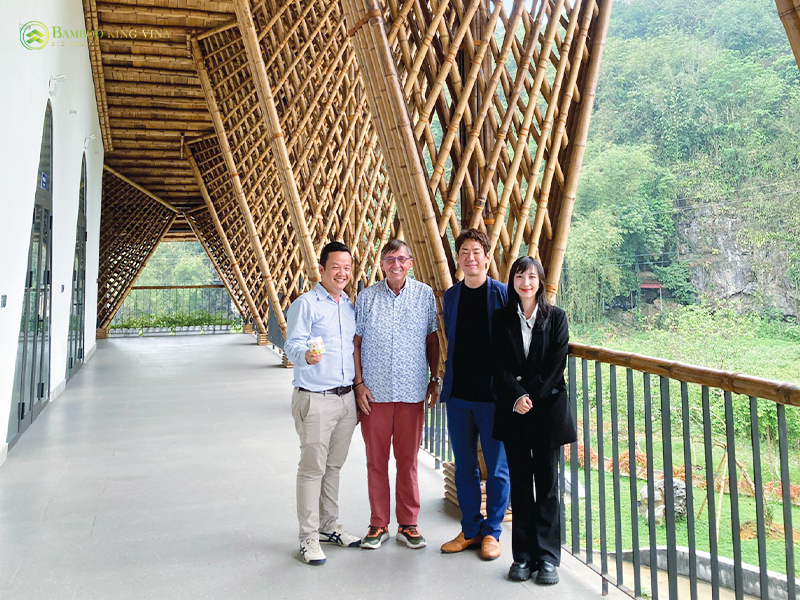

Situated in the dynamic industrial area of Vietnam, Bamboo King Vina symbolizes innovation and high standards in bamboo processing. It is not only a factory but more like an extensive facility where resilient bamboo is converted into a wide range of high-quality panels, each carefully designed to address the specific needs of various clients. Recognized as the “largest and most advanced industrial bamboo manufacturer in Vietnam,” Bamboo King Vina has established itself as a key player in both local and global markets, serving architects, designers, construction companies who appreciate the natural beauty, sustainability, and durability of bamboo.

At the core of Bamboo King Vina’s business is a strong focus on customization. Unlike products made in bulk, their bamboo panels are not simply produced in uniform sizes and finishes. Each order is viewed as a unique project, combining the client’s vision with Bamboo King Vina’s technical skills. This personalized method is a fundamental part of their manufacturing philosophy, understanding that the true capabilities of bamboo can only be realized when it is adapted to specific uses, such as stylish interior cladding, sturdy furniture parts, long-lasting flooring, or detailed architectural features.

The Journey from Culm to Customized Panel: A Symphony of Precision and Innovation

The journey of a Bamboo King Vina panel begins with the careful selection of mature bamboo culms, sourced from sustainably managed plantations across Vietnam. This initial stage is critical, as the quality and characteristics of the raw material directly influence the final product. Only bamboo that has reached optimal maturity, exhibiting the desired density, strength, and straightness, is chosen for processing. This rigorous selection process underscores Bamboo King Vina’s dedication to quality right from the very source.

Once the selected culms arrive at the state-of-the-art factory, they undergo a series of sophisticated transformations, each designed to enhance the material’s inherent properties and prepare it for its final, customized form. The initial processing involves cleaning, cutting, and splitting the bamboo into strips or fibers, depending on the type of panel being manufactured. This meticulous breakdown of the raw material allows for the removal of the outer skin and the inner pith, resulting in a more uniform and structurally sound base material.

The next crucial step in Bamboo King Vina’s process is often the application of advanced treatment technologies. Recognizing that natural bamboo, while strong, can be susceptible to moisture, insects, and fungal growth, Bamboo King Vina employs cutting-edge techniques to enhance its durability and longevity. One such technology is hydrothermal modification, a process that involves subjecting the bamboo to high temperatures and steam under controlled conditions. This process alters the chemical structure of the bamboo, making it more resistant to swelling, shrinking, and biological degradation. The result is a significantly more stable and durable material, capable of withstanding a wider range of environmental conditions.

Another innovative technology utilized by Bamboo King Vina is Nano Calcium infusion. This proprietary process involves impregnating the bamboo fibers with nano-sized calcium particles, further enhancing its strength, hardness, and resistance to pests. The Nano Calcium infusion penetrates deep into the cellular structure of the bamboo, providing long-lasting protection without compromising the material’s natural beauty or workability. These advanced treatment methods are a testament to Bamboo King Vina’s commitment to producing bamboo panels that not only meet but exceed industry standards for quality and durability.

The Art of Customization: Tailoring Bamboo to Client Specifications

With the base material treated and prepared, the focus shifts to the core of Bamboo King Vina’s value proposition: customization. This is where the client’s specific requirements take center stage. The manufacturing process is highly flexible, allowing for a wide array of modifications to the bamboo panels, including:

- Dimensions: Clients can specify the exact length, width, and thickness of the panels required for their project, eliminating waste and ensuring a perfect fit.

- Construction: Bamboo King Vina offers various construction methods, including vertical grain, horizontal grain, and strand woven panels, each with its unique aesthetic and structural properties. Vertical grain panels showcase the linear beauty of the bamboo culm, while horizontal grain panels highlight the nodes and create a more textured appearance. Strand woven bamboo, produced by compressing bamboo fibers under high pressure, offers exceptional density and hardness, making it ideal for high-traffic applications.

- Finishes: A wide range of surface finishes can be applied to the panels, from natural oil finishes that enhance the bamboo’s inherent color and grain to stains and lacquers that provide specific aesthetic effects and levels of protection. Clients can choose from matte, satin, or high-gloss finishes to achieve their desired look.

- Machining: Bamboo King Vina’s advanced machinery allows for precise cutting, shaping, drilling, and profiling of the panels according to the client’s design specifications. This capability is particularly valuable for projects requiring intricate details or complex joinery.

- Special Treatments: Beyond the standard durability treatments, Bamboo King Vina can also apply specialized treatments such as fire retardants or acoustic dampening layers, catering to specific performance requirements.

The ability to tailor every aspect of the bamboo panel to the client’s needs is a key differentiator for Bamboo King Vina. Their team of experienced engineers and technicians works closely with clients throughout the design and manufacturing process, providing expert advice and ensuring that the final product meets their exact specifications and performance expectations. This collaborative approach fosters a strong partnership between Bamboo King Vina and its clients, built on trust and a shared commitment to quality and innovation.

Applications Across Industries: The Versatility of Customized Bamboo Panels

The customized bamboo panels produced by Bamboo King Vina find applications across a wide spectrum of industries, a testament to the material’s versatility and the factory’s ability to tailor it to specific needs. Some key applications include:

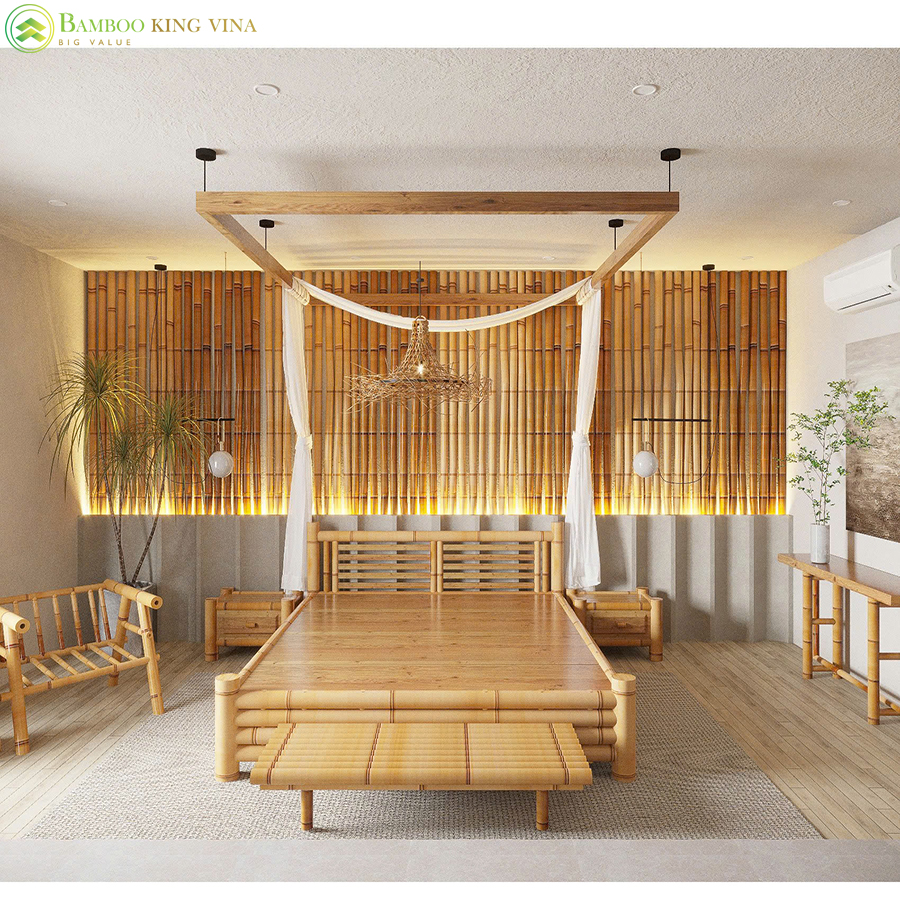

- Interior Design and Architecture: Bamboo panels are increasingly favored by architects and designers for their aesthetic appeal, sustainability, and structural properties. They are used for wall cladding, ceiling panels, flooring, doors, window frames, and decorative elements, adding a touch of natural elegance and warmth to interior spaces.

- Furniture Manufacturing: The strength, durability, and workability of bamboo panels make them an excellent material for crafting high-quality furniture, from tables and chairs to cabinets and shelving units. The ability to customize thickness and construction allows manufacturers to create furniture that is both aesthetically pleasing and structurally sound.

- Construction and Infrastructure: Strand woven bamboo panels, in particular, offer exceptional strength and density, making them suitable for certain structural applications, including flooring in high-traffic areas, formwork for concrete, and even some load-bearing elements in sustainable construction projects.

- Transportation: The lightweight yet strong nature of bamboo panels makes them a viable material for interior components in the transportation industry, such as wall and ceiling panels in trains, buses, and even boats.

- Specialty Products: Bamboo King Vina also caters to niche markets, producing customized panels for applications such as musical instruments, skateboards, and other specialized products where the unique properties of bamboo are highly valued.

Sustainability at the Core: Bamboo as a Responsible Choice

Beyond its versatility and customizability, bamboo’s inherent sustainability is a cornerstone of Bamboo King Vina’s ethos. Bamboo is one of the fastest-growing plants on Earth, with some species growing up to a meter per day. This rapid growth rate makes it a highly renewable resource, capable of being harvested sustainably without causing deforestation. Bamboo also requires significantly less water and fewer pesticides than traditional timber, further reducing its environmental impact.

Bamboo King Vina is committed to responsible sourcing and manufacturing practices, ensuring that the bamboo they use comes from sustainably managed plantations and that their production processes minimize waste and environmental impact. By choosing customized bamboo panels from Bamboo King Vina, clients are not only investing in a high-quality and versatile material but also making a conscious choice to support sustainable development.

Looking to the Future: Innovation and Collaboration

As the demand for sustainable and high-performance materials continues to grow, Bamboo King Vina is poised to play an increasingly significant role in the global market. Their commitment to innovation, exemplified by their advanced treatment technologies and flexible manufacturing processes, allows them to continuously push the boundaries of what is possible with bamboo. Furthermore, their collaborative approach to working with clients fosters strong partnerships and ensures that their customized bamboo panels meet the evolving needs of a diverse range of industries.

In conclusion, Bamboo King Vina’s factory in Vietnam is not just a place where bamboo panels are made; it is a hub of innovation, precision, and customization. Their ability to transform this remarkable natural resource into tailored solutions, combined with their commitment to quality and sustainability, makes them a truly unique and valuable partner for anyone seeking the exceptional properties and aesthetic beauty of bamboo. Whether it’s a large-scale architectural project or a bespoke furniture design, Bamboo King Vina stands ready to bring your vision to life with the perfect bamboo panel, made precisely to your order

Contact Us to Become Your Trusted Partner for All Your Bamboo Needs

If you are seeking a reputable and reliable partner in the supply chain of raw materials for bamboo products.

Located in the heart of Vietnam’s largest bamboo resource area, Bamboo King Vina is confident in being your trusted strategic partner. With leading production scale, advanced technology, and a team of experienced experts and engineers, we offer a diverse range of bamboo products such as bamboo veneer, bamboo flooring, and accept custom manufacturing according to all requirements.

Contact the experts and engineers at Bamboo King Vina factory right away for the best consultation and support for your needs!

——————————-

Contact information:

Email: sales@bambooking.vn

Whatsapp: +84 90 457 76 18

Website: Bambookingvina.com

Bamboo King Vina – Your trusted bamboo partner worldwide