In response to growing demand for sustainable and durable materials, the construction and furniture industries are moving beyond traditional plywood—which, despite its versatility, raises concerns over environmental impact and limited longevity. As greener alternatives gain attention, bamboo and advanced processes like hydrothermal treatment from BKV stands out as a high-performance material redefining modern standards for strength, durability, and sustainability.

Understanding Plywood and Its Limitations plywood bamboo

Plywood has earned its reputation for strength, affordability, and versatility, widely used in furniture, cabinetry, flooring, and structural applications. Made by compressing layers of wood veneer, it offers a balance of rigidity and flexibility. However, its production methods and material limitations raise concerns about durability and environmental impact—driving the industry to explore more sustainable, long-lasting alternatives.

Definition and Composition of Plywood plywood bamboo

Plywood is made by bonding multiple thin layers of wood veneer—known as plies—with each layer’s grain oriented perpendicular to the next for added strength and stability. Typically sourced from softwoods like pine or fir, and occasionally hardwoods, the inner layers provide structure while the outer layers define appearance. Special adhesives may be used to enhance moisture or fire resistance; however, many contain formaldehyde-based resins, raising concerns about health and environmental safety, particularly in lower-grade products.

Common Uses of Plywood in Furniture and Construction bamboo plywood vietnam

Plywood’s popularity stems from its affordability, versatility, and ease of use.

• Furniture Manufacturing: Commonly used in cabinets, shelves, and panels due to its smooth surface for finishing.

• Flooring & Walls: Acts as subflooring or decorative panels, offering strength and uniform load distribution.

• Construction: Used in roofing, formwork, and structural walls for its durability.

• Transport & Packaging: Lightweight yet strong, ideal for crates and pallets.

Despite these strengths, plywood’s environmental drawbacks have prompted a shift toward more sustainable and durable materials.

Key Limitations of Plywood bamboo

While plywood offers many benefits, its drawbacks are becoming more apparent in the context of sustainability and durability.

- Environmental Concerns: The production of plywood involves cutting down trees, which contributes to deforestation and loss of biodiversity. Moreover, the adhesives used, especially those containing formaldehyde, release volatile organic compounds (VOCs), impacting indoor air quality and health.

- Limited Lifespan and Weather Resistance: Standard plywood is susceptible to water damage, mold, and decay if not properly sealed, limiting its use in outdoor or moisture-prone environments.

- Structural Limitations: Although strong, plywood can warp, delaminate or crack under stress or over time, especially with exposure to environmental factors without appropriate protective coatings.

- Material Waste and Inefficiency: The production process results in significant waste due to defects, knots, or uneven veneers, impacting overall sustainability.

Given these limitations, the industry’s shift toward more eco-friendly, durable, and high-performance materials becomes essential. The search for sustainable alternatives such as hydrothermal processes is gaining momentum.

Introduction to Hydrothermally-Modified Wood as an Alternative Material

Hydrothermally-modified wood is gaining recognition across furniture, architecture, and construction industries for its enhanced durability, environmental performance, and versatility. Through controlled heat and moisture treatment—without the use of harmful chemicals—this wood becomes a powerful substitute for traditional materials like plywood.

Overview of Hydrothermally-Modified Wood Properties

This innovation involves subjecting natural wood species (such as ash, pine, or poplar) to high-temperature steam processing. The result is a material that resists moisture, decay, and deformation far better than untreated wood. Hydrothermal treatment enhances dimensional stability, extends lifzespan, and improves the overall performance of the wood—making it ideal for indoor applications that demand long-term resilience and aesthetic consistency.

Advantages of Using Hydrothermally-Modified Wood in Furniture and Construction

The appeal of hydrothermally-treated wood lies in its combination of sustainability, physical performance, and environmental safety:

- Eco-Friendly and Renewable: Sourced from sustainably managed forests, treated wood eliminates the need for chemical preservatives while maintaining renewability.

- Improved Durability: The treatment alters the wood’s cell structure, reducing water absorption, minimizing swelling or shrinking, and increasing resistance to rot and insects.

- Design Versatility: Treated wood retains a natural look while achieving a refined, high-end finish. It can be stained, polished, or shaped to fit various design styles.

- Cost-Effective Over Time: Longer service life and low maintenance requirements make it a practical alternative to conventional plywood and MDF boards.

Applications of Hydrothermally-Modified Wood in Industry

Thanks to its enhanced characteristics, hydrothermally-modified wood is increasingly used across a range of indoor applications:

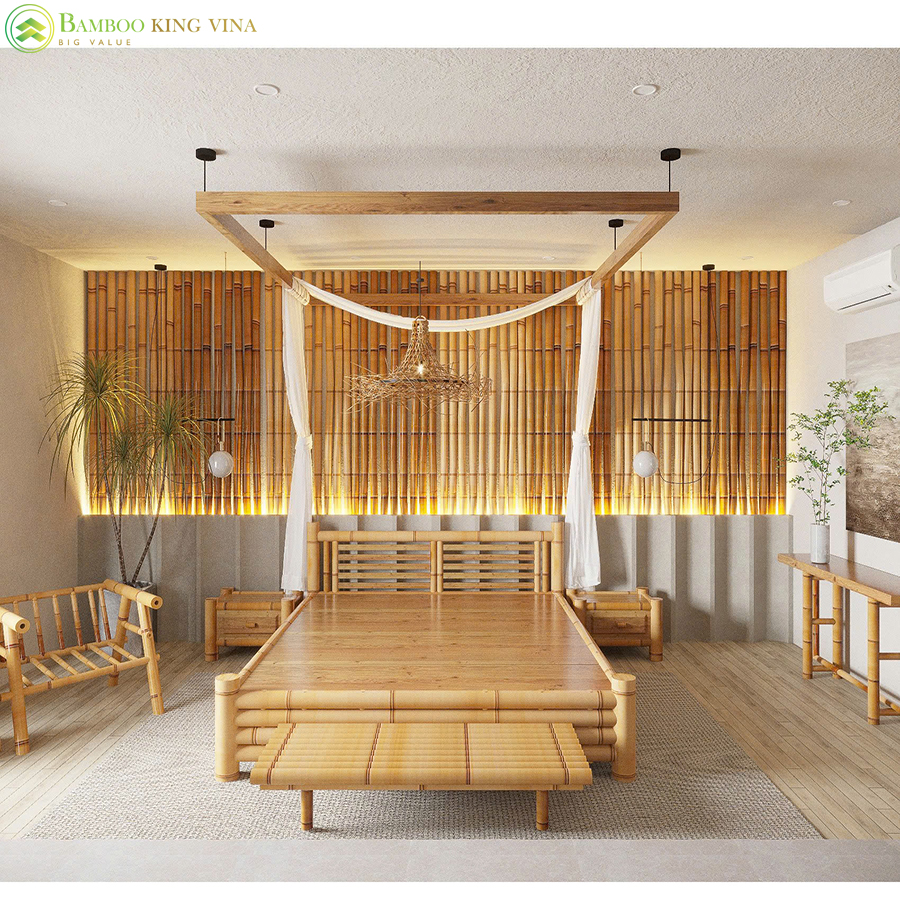

- Furniture & Fixtures: Tables, cabinetry, wall panels, and interior cladding with enhanced longevity.

- Flooring Substrates & Decorative Panels: Used where visual appeal meets moisture resistance.

- Sustainable Architecture: Eco-friendly projects benefit from its natural look and durability without sacrificing environmental values.

- Interior Design Projects: From hotels to residential interiors, designers appreciate its premium finish and stability.

Invention for Innovation at BKV: Setting New Standards

Bamboo King Vina’s hydrothermally-modified wood represents the next generation of sustainable materials. With a focus on low-emission processing and high-performance output, BKV’s solutions support eco-conscious building without compromising design or durability. As global markets shift toward greener construction and manufacturing, hydrothermally-treated wood is setting new standards for what’s possible in modern material innovation.

What is Hydrothermal Modification?

Hydrothermal modification is an eco-friendly process that enhances wood by treating it with controlled heat and moisture. This alters the wood’s cell wall chemistry, reducing moisture absorption and increasing resistance to biological degradation—all without harmful chemicals. The treatment improves durability, stability, and performance across various wood species, including bamboo and softwoods, making it a sustainable alternative to conventional treatments.

Benefits of Hydrothermally-Modified Wood bamboo plywood

The advantages of hydrothermally-modified wood are extensive, offering effective solutions to many limitations of traditional wood products:

- Enhanced Durability and Biological Resistance: The treatment makes wood more resistant to mold, fungi, and insects, significantly extending its lifespan—without the use of chemical preservatives.

- Increased Dimensional Stability: By reducing the wood’s moisture absorption, hydrothermal modification minimizes swelling and shrinking, ensuring better performance in fluctuating environments.

- Environmental Friendliness: This chemical-free process is safer for workers and end-users and meets the rising demand for sustainable, low-impact building materials.

- Improved Fire Resistance: Although not fireproof, treated wood shows reduced flammability and slower combustion, contributing to safer construction and interior applications.

- Better Mechanical Properties: Hardness, stiffness, and sometimes tensile strength are improved, making the wood more durable for load-bearing or high-wear uses.

How BKV Implements Hydrothermal Modification plywood bamboo

BKV enhances wood and bamboo through a proprietary hydrothermal treatment that precisely controls temperature, humidity, and duration to optimize durability while preserving structural integrity. High-quality raw materials are conditioned in specialized chambers where moisture and internal chemistry are adjusted, transforming lignin and hemicellulose to boost resistance against water, pests, and decay.

After treatment, each product is finished and quality-tested for uniformity and performance. The result is a sustainable, high-performance material ideal for furniture, flooring, and panels—offering a viable alternative to traditional plywood, especially in humid or demanding environments.

Recent Market Trends in Sustainable Building Materials bamboo plywood

The industry landscape is shifting rapidly toward sustainability, driven by regulatory policies, consumer preferences, and corporate social responsibility initiatives.

- Growth of Green Certifications: Certifications like FSC, BSCI, and SMETA recognize materials that meet sustainability criteria, often favoring bamboo and modified wood.

- Innovation Adoption: Companies are investing in research to improve processing efficiency, reduce costs, and expand applications of bio-based materials.

- Supply Chain Development: As demand grows, supply chains for bamboo and environmentally modified woods are stabilizing, encouraging wider adoption.

- Consumer Preferences: Eco-conscious consumers are increasingly seeking furnishings and homes made from sustainable materials, further bolstering market growth.

These trends signify a cultural and economic shift emphasizing the importance of environmentally responsible material choices.

Hydrothermal-modified wood in furniture & construction

Here are some testimonials from our clients of using hydrothermal-modified wood in furniture & construction, where sustainability becomes the vision.

Conclusion

The shift toward sustainable materials in furniture and construction is accelerating, with bamboo emerging as a fast-growing, eco-friendly alternative to traditional plywood. When enhanced through hydrothermal modification—like BKV’s advanced treatment—these materials address key plywood limitations, offering superior durability, moisture resistance, and reduced maintenance. As demand for eco-conscious solutions grows, hydrothermally-modified wood represents a smart, future-ready choice that balances performance with environmental responsibility.