- Product name: Laminated wood

- Produce code:

- Structure: hydrothermal modification according to the ISO 13061-2:2014 standard

- Color: Can be customized upon request

- Category: Poplar, Ash, Pine, Oak

- Our dimensions (or customize your own)(inch):

Length: 10-96

Width: 3 – 48

Thickness: ⅜ – 4

- Surface Hardness: 1,32 (N/mm2) according to % EN 13329:2016 standard

- Expansion rate or water absorption: 1,84%

- Formaldehyde emission = E1/E0

- Finish: 2K or UV coating

- Moisture content: 10+-2% according to TCVN 13707-1:2023 (Equivalent to ISO 13061-1:2014 with Amendment 1:2017)

- Termite Resistance: Rated Level 3 according to TCVN 11355:2016.

- Mold and Stain Fungus Resistance: Rated Level 3 according to TCVN 11356:2016.

- Features: Minimizes warping, shrinkage, cracking, and termite damage. Reduces swelling, prevents brittleness and chipped edges. Improves static bending strength (MOR) and parallel grain strength, while enhancing color stability.

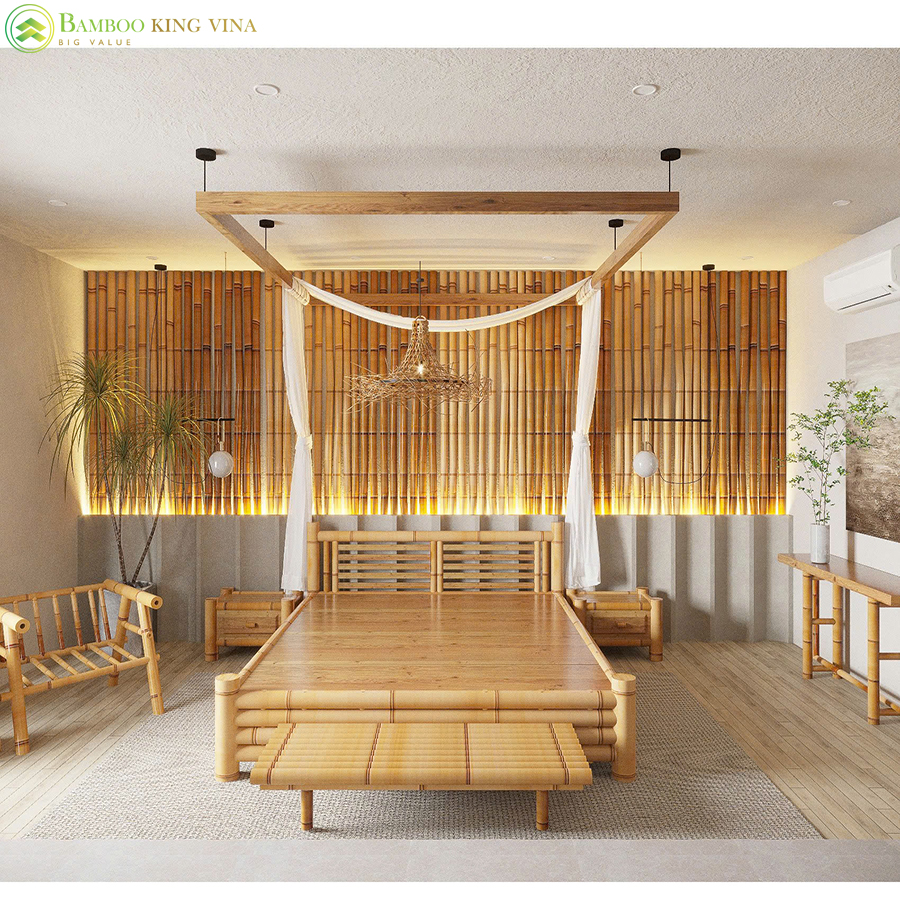

- Applications: flooring, interior furniture