Which Bamboo Flooring Factory in Vietnam Stands Out? Looking to source bamboo flooring from Vietnam but not sure where to start? This comparison guide breaks down the strengths of leading factories—from product quality and sustainability to customization options and export support—so you can make an informed decision for your next build or brand.

Overview of Bamboo as a Flooring Material

Bamboo has gained widespread recognition as a sustainable and stylish alternative to traditional hardwood flooring. Technically a grass, bamboo offers high tensile strength, dimensional stability, and natural resistance to moisture and pests—making it an ideal candidate for flooring in residential and commercial spaces alike. With processing techniques such as strand-woven compaction and thermal modification, bamboo can match or exceed the performance of oak or maple in high-traffic environments.

The Growing Popularity of Bamboo Flooring

Global demand for eco-conscious building materials has made bamboo flooring increasingly popular among architects, developers, and retailers. Its aesthetic flexibility—from natural tones to deep stains and textured finishes—caters to a wide spectrum of interior design styles, including minimalism, coastal, industrial, and rustic. Additionally, the affordability and fast-growing nature of bamboo contribute to its appeal as a renewable alternative to slow-growing hardwood species.

Why Vietnam is a Leading Production Hub

Vietnam has become one of the world’s most important production hubs for bamboo products—including flooring—due to its rich natural bamboo resources, skilled labor, and investments in manufacturing infrastructure. The country’s proximity to key export markets and long-standing expertise in wood processing have positioned it as a global supplier of both raw materials and finished products. Factories in Vietnam are also increasingly focused on sustainable production, using FSC-certified bamboo and adhering to international environmental and quality standards.

What to Look for in a Bamboo Flooring Factory

Quality of Materials and Product Consistency

When sourcing bamboo flooring from Vietnam, quality begins with material selection. The best factories use mature, sustainably harvested bamboo—often aged 4–6 years—for optimal hardness and stability. Buyers should look for facilities that follow rigorous quality control protocols across every production stage, from lamination and pressing to finishing and packaging. Consistency in color, density, and moisture content is essential for batch-to-batch reliability, especially for large-scale projects or multi-phase developments.

Customization Capabilities and Product Range

Top-tier bamboo flooring factories offer a broad product portfolio and strong customization flexibility. This includes:

- Strand-woven or vertical/horizontal bamboo construction

- A variety of finishes: matte, gloss, stained, brushed, or distressed

- Custom sizing and edge profiling (e.g., tongue & groove, click-lock)

- Add-ons like fire-retardant or UV-resistant coatings.Bamboo Flooring Factory in Vietnam

A factory’s ability to tailor products for OEM or private-label clients significantly boosts brand value and product differentiation in competitive markets.

Certifications and Sustainability Commitments

Sustainability is more than a marketing claim—it should be evident in factory practices. Leading Vietnamese bamboo flooring manufacturers provide certifications such as:

- FSC (Forest Stewardship Council)

- ISO 9001 (quality management)

- CE Marking for European standards

- E0/E1 formaldehyde emissions ratings.Bamboo Flooring Factory in Vietnam

These credentials demonstrate a commitment to ethical sourcing, worker safety, and low-emission production processes. Buyers seeking to align with green building standards (such as LEED or WELL) should prioritize factories that offer traceable, eco-certified materials.

Pricing, Lead Time, and Export Support

Competitive pricing remains one of Vietnam’s strongest advantages. However, cost must be evaluated alongside lead time, payment terms, and logistical support. A reliable bamboo flooring manufacturer will:

- Offer transparent pricing structures

- Provide realistic production and delivery schedules

- Support export compliance with clear documentation (CO, packing list, invoice)

- Accommodate OEM labeling and custom packaging

Look for factories with a strong track record of timely international deliveries and a dedicated team that can manage end-to-end export processes.

Overview of Leading Bamboo Flooring Factories in Vietnam

As Vietnam continues to establish itself as a global hub for sustainable materials, its bamboo flooring industry has seen rapid growth. Among the many manufacturers, three factories stand out for their product range, innovation, and export capabilities: BWG Bamboo Vietnam, Vietbamboo Co., Ltd, and Bamboo King Vina.

BWG Bamboo Vietnam: Product Range and Market Focus

BWG Bamboo is a long-established manufacturer located in Thanh Hoa Province. The company offers an extensive product range that includes solid bamboo flooring, strand-woven bamboo flooring, and bamboo panels. Their operations are geared toward the EU and North American markets, with a strong emphasis on quality and compliance.

Key highlights:

- Focus on environmentally certified bamboo flooring (FSC-certified)

- Supplies for indoor and outdoor applications

- Available in multiple finishes, grains, and installation systems

- Caters largely to importers, distributors, and large-scale project developers .Bamboo Flooring Factory in Vietnam

BWG has a robust production capacity and emphasizes durability, moisture resistance, and VOC-safe finishes, aligning with Western quality standards.

Vietbamboo Co., Ltd: Competitive Strengths and Innovations .Bamboo Flooring Factory in Vietnam

BWG has a robust production capacity and emphasizes durability, moisture resistance, and VOC-safe finishes, aligning with Western quality standards.

Based in Hanoi, Vietbamboo Co., Ltd has been in operation since 2009 and is known for innovation in laminated bamboo products. The company offers custom bamboo flooring, decking, plywood, panels, and furniture parts, supported by a skilled workforce and modern machinery.

Competitive advantages:

- Strong R&D capacity for customized OEM and ODM solutions

- Uses both vertical and horizontal grain constructions

- Offers dyed and carbonized bamboo flooring for varied aesthetics

- Export experience spans Europe, Australia, and the U.S

BWG has a robust production capacity and emphasizes durability, moisture resistance, and VOC-safe finishes, aligning with Western quality standards.Bamboo Flooring Factory in Vietnam

Vietbamboo is particularly attractive for clients looking for high-flexibility production runs and a balance of pricing with moderate to high quality.

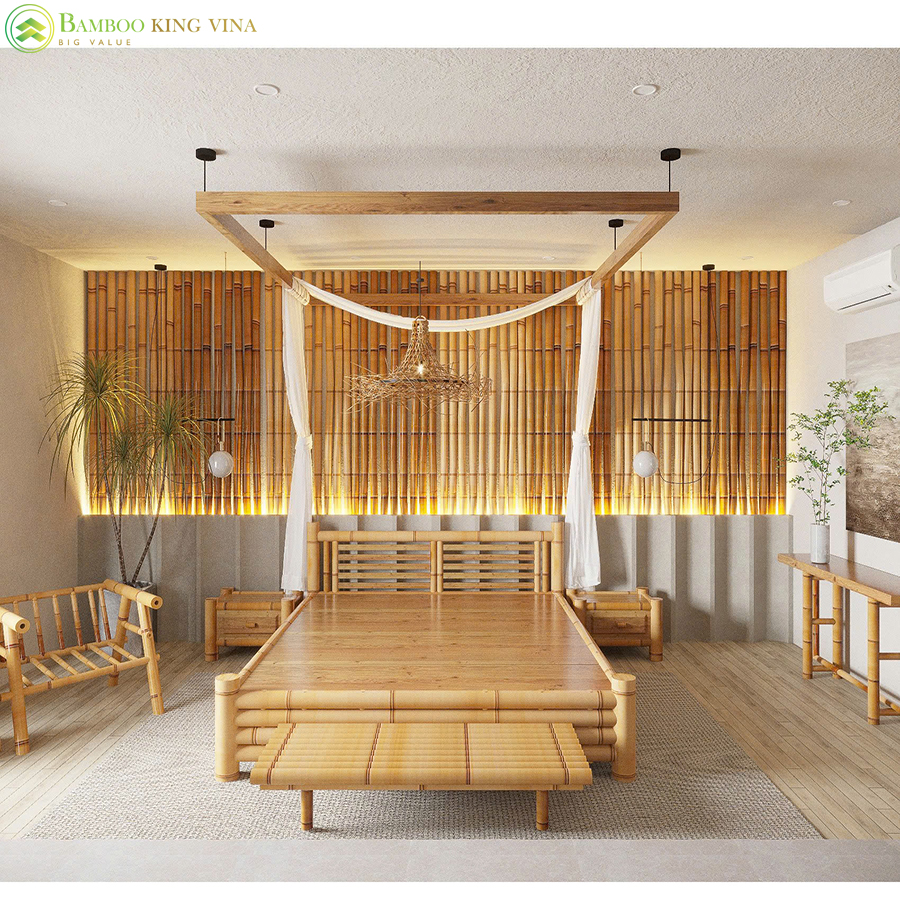

Bamboo King Vina: Sustainability-Driven Manufacturing

Bamboo King Vina operates one of the largest bamboo and wood product factories in Vietnam, with over 75,000 m² of manufacturing space and a capacity of 120,000 m² of finished wood products annually. While its focus includes bamboo home goods, panels, and furniture, its flooring segment stands out for high customization and sustainability.

Core strengths:

- Large-scale hydrothermal wood and bamboo flooring lines

- Automated CNC, UV coating, and finger-jointing equipment for precision

- Emphasis on traceable sourcing and non-toxic treatments

- Flexible MOQ and custom dimensions for OEM/ODM partners.Bamboo Flooring Factory in Vietnam

Bamboo King Vina is ideal for B2B customers needing custom solutions at competitive pricing, especially for eco-conscious brands.

Simple Factory Comparison Summary

Key Strengths Side-by-Side

|

Factory |

Core Product Strength |

Machinery & Tech |

Sustainability Focus |

|

BWG Bamboo |

Flooring & Panels |

Advanced drying, pressing |

FSC-certified materials |

|

Vietbamboo Co., Ltd |

Flooring, Furniture, Plywood |

Custom lamination |

Moderate |

|

Bamboo King Vina |

Flooring, Doors, Panels |

CNC, UV, hydrothermal |

High – traceable sourcing |

Target Customer Fit

|

Factory |

Best For |

|

BWG Bamboo |

Distributors, Retail Brands, Green Builders |

|

Vietbamboo Co., Ltd |

OEM/ODM clients, wholesalers, boutique brands |

|

Bamboo King Vina |

Contractors, Developers, Exporters |

Price Range & Minimum Order QuantitiesBamboo Flooring Factory in Vietnam

- BWG Bamboo: Mid to High pricing; MOQs often 500–1,000 m² depending on product.

- Vietbamboo: Moderate pricing; MOQs start as low as 200–300 m².

- Bamboo King Vina: Competitive pricing due to factory scale; flexible MOQs on request.

Certifications and Export CapabilitiesBamboo Flooring Factory in Vietnam

|

Factory |

Certifications |

Export Markets |

|

BWG Bamboo |

FSC, CE, ISO |

EU, US, Canada, Japan |

|

Vietbamboo Co., Ltd |

ISO 9001, internal QA |

US, Australia, EU |

|

Bamboo King Vina |

CE-compliant, in-process ISO |

U.S., Korea, EU, Middle East |

Which Factory Is Right for You?Bamboo Flooring Factory in Vietnam

Matching Factory Strengths to Your Business Type

- Distributors or importers: BWG Bamboo offers the scale, certification, and consistency.

- OEM/ODM brands: Vietbamboo excels in custom product development and flexibility.

- Project developers and contractors: Bamboo King Vina delivers fast, high-volume custom solutions at excellent price points.

All three factories offer sampling programs and accept trial orders for qualified B2B clients. Visiting their showrooms or requesting product catalogs is recommended before full-scale procurement.

Vietnam is fast becoming a global hub for bamboo flooring, thanks to its sustainable innovation and strong manufacturing base. By aligning your project needs with the right factory—whether it’s BWG Bamboo, Vietbamboo, or Bamboo King Vina—you gain a reliable partner for scalable, high-quality, and eco-conscious solutions.

Contact Bamboo King Vina today to discuss your specific bamboo processing needs and discover why we are the trusted choice for businesses around the world. Let us be your reliable partner in realizing your vision with the exceptional material that is bamboo. You can contact the representative of the Voyage Vietnam – Tonkin Vietnam Travel